Your cart is currently empty!

Tapping Trees & Making Maple Syrup with Kids

The process of making maple syrup is one that absolutely fascinates me. The whole concept of tapping trees, collecting sap and creating your own syrup is something I’ve been curious about and interested in for years! Today, the amazing and inspiring Leslie Alvis is back sharing her family’s adventures in tapping trees and making maple syrup on their family cattle farm in Ohio. The Alvis family takes maple syrup seriously. They have nearly 300 taps and quite the set-up. While this may not be practical for everyone wanting to try their hand at making maple syrup, it is absolutely fascinating and you’re sure to learn a lot about the process and walk away with a newfound appreciation for the hard work and dedication that goes into making delicious treat!

Winter is ending

Every year, just when Ohio winters have reached the peak of their monotony and we’re not sure if we can’t survive another week of dreary coldness, a subtle shift occurs. You can smell it in the air when you step outside in a crisp February dawn – a hint of green, of dirt, of life. It can be heard it in the trees, as the bird cacophony increases. You can feel it in the ground, as the frozen dirt begins to soften. In the rhythm established by our great Creator, the world is waking up.

And we are ready. The end of winter means the days are lengthening and temperatures are finally rising. Although, by this time cabin fever has become a very real malady, and we are overtaken by another sort of seasonal madness: maple sugaring! Each year our family heads to the woods in these late winter days to begin the age-old process of making maple syrup.

Maple sugaring

For hundreds of years, residents of the North American continent have tapped holes in maple trees in late winter. They’ve collected the sweet sap that flows through the trees as the days warm above freezing, and boiled it down into pure maple syrup. The Native Americans taught this process to the early settlers and the tradition has continued throughout the years, changing and adapting with inventions and technology.

Today, major producers in the maple syrup industry tap hundreds of trees. They collect the sap through a vacuum tubing system and boil it down in huge, state-of-the-art evaporators. On the other side of the scale are the small hobby producers, who tap a handful of trees in their yards and boil the sap in a single pan. Our operation falls somewhere in the middle. We put in between 250-300 taps each year, collect it in buckets, and boil it down in a moderate sized wood-fired evaporator.

A family affair

Maple sugaring is a family affair for us. We began this enterprise, together with my parents, 6 years ago. My husband had dreamed of making maple syrup for years. My parent’s farm has acres and acres of woods with hundreds of maple trees. After talking about it for ages, we finally decided to give maple syrup making a try. We went to a local maple supply store with the idea that we would just dip our toes in the water, so to speak. We thought we’d put a few taps out in Dad’s woods, boil the sap on a propane burner and see what happened. Somehow, with a little education and evaluation of our woods’ potential, this plan quickly escalated into a full-blown project.

We bought a used 2’x6′ evaporator, put in a lot of hours scrubbing it up, and began tapping trees. Before the first week was over, we were back at the maple store buying more taps. Only our limited manpower and evaporator capacities have kept us limited to 300 taps!

We include our children in every part of it. From washing buckets to tapping trees, gathering sap, splitting and hauling wood for the evaporator. Making syrup is a huge amount of work, but it is also a grand adventure. The children love being in the woods….as long as we keep their hands and feet warm and their tummies fed. I learned early on to have snacks, lots of them. And a full change of clothes for every child. Those two things are key to making sure the kids have fun throughout the long days we spend making syrup.

Timing is key

Our “sugar bush” (stand of maple trees) is tucked deep in my dad’s woods, down the road a half a mile from the main farm. The sap begins to flow when the days rise into the 40s and the nights fall below freezing. Producers like us who have open taps have a 6-week window once we put in the taps. After that, we risk harmful bacteria getting into the trees. So we watch the weather carefully to decide when to tap. As soon as we see a weather pattern of days well above freezing with nights still dropping into the 20s, we start putting in taps and the clock is ticking.

Tap carefully

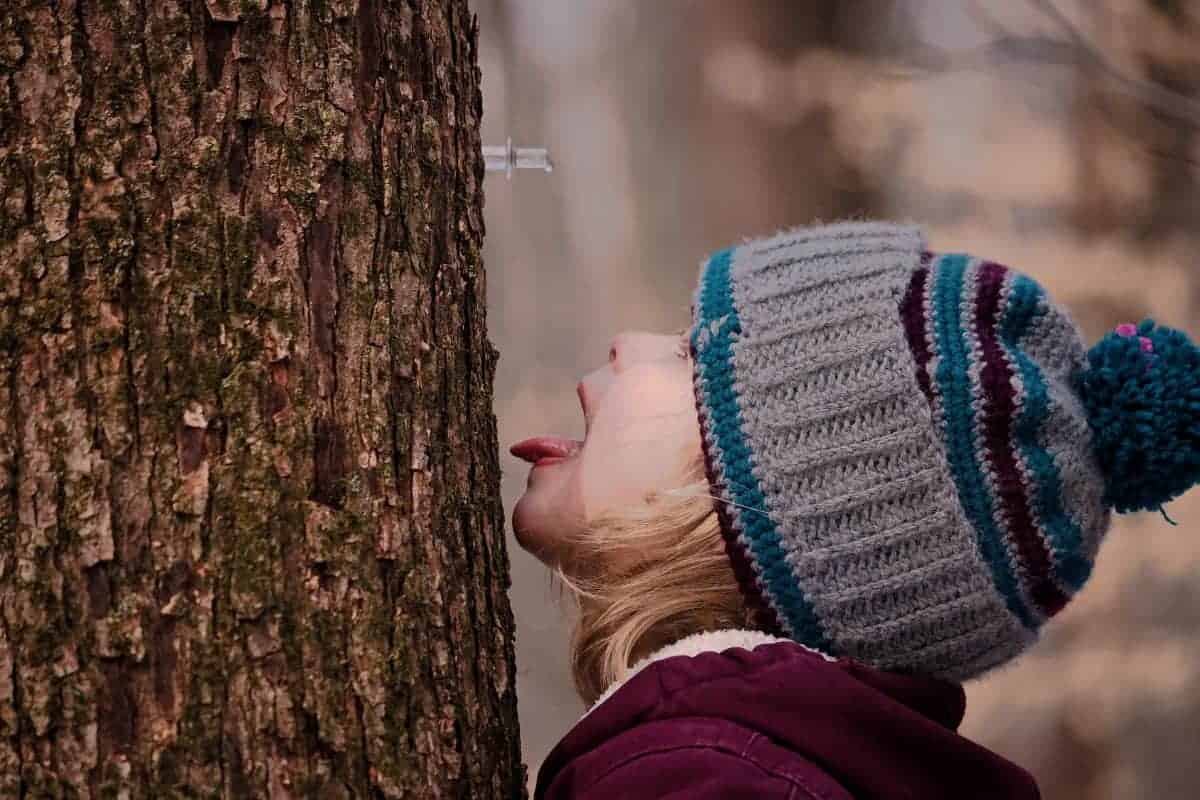

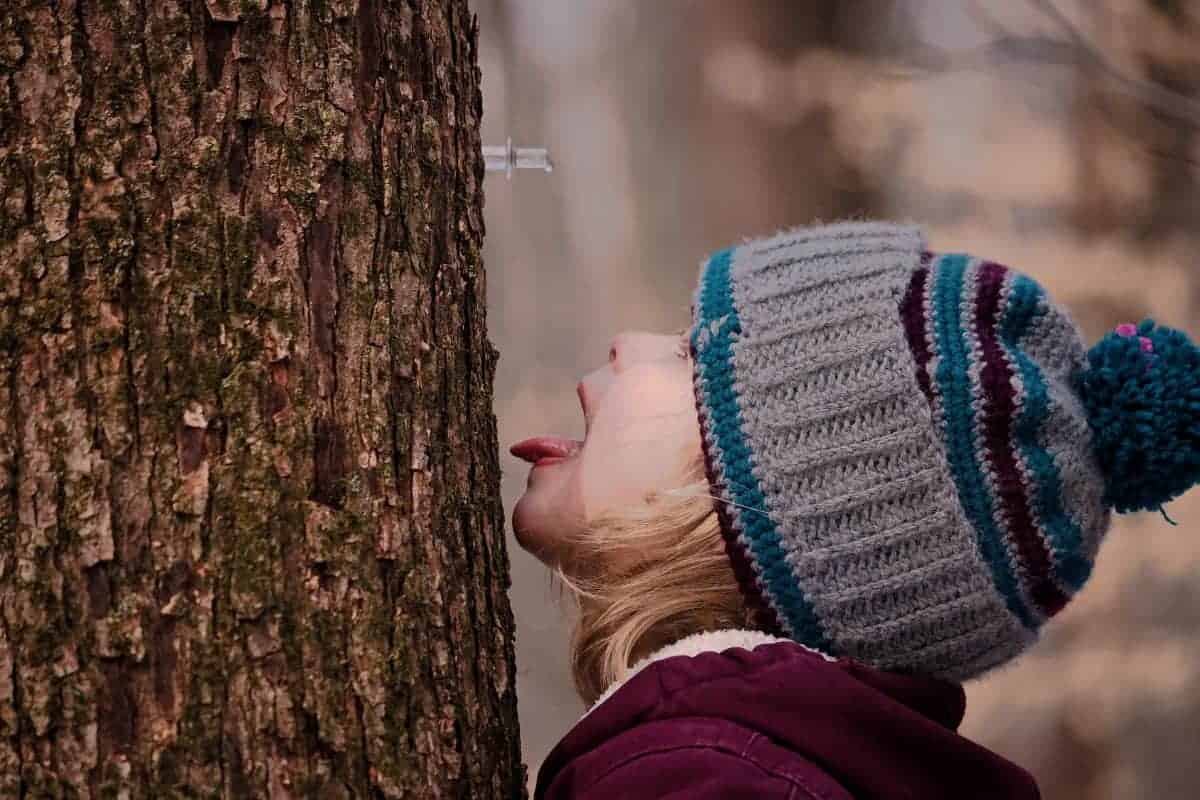

We tapped our trees on a chilly day in late February this year, with snow still on the ground but sun warming the trees. The trees immediately began dripping sweet sap into the buckets, and the beginning of a new season filled the air with excitement as we hurried from tree to tree. The children raced around with buckets, handing them off to their dad, uncle, and grandpa as they drilled holes 1.5” deep in the trees.

There’s a careful science to tapping trees responsibly to avoid injuring the tree and to allow for the best yield. We don’t tap any trees under a 12” diameter, giving them time to grow. A large tree can support 2-4 taps, and our largest tree has 5 buckets hung from it! We move the position of the taps in each tree from year to year, allowing the tree to heal up and continue to grow and be healthy.

Old-fashioned fun

When the sap is running, it has to be gathered and boiled frequently or it will spoil. So when the days warm up, we head out every day to gather sap. We haul 55-gallon barrels out to the sugar bush on a trailer behind a four-wheeler. Everyone tall enough to carry a bucket grabs a couple and we start going from tree to tree, emptying the buckets from the trees, then carrying each bucketful to the barrels. This is the old-fashioned way to gather sap, and there is no way to make it easy. But as long as it’s not pouring rain and the four-wheeler doesn’t get stuck in the mud, we have a lot of fun.

We are trying to teach the kids that they can work hard and have fun at the same time. Fun conversation, cheerful encouragement, and frequent smiles as we trudge through the woods remind us that our attitudes make all the difference. Despite the heavy work that needs done, we are doing this because we love it. After all, the woods are one of our favorite places to be. And making syrup is a fascinating and fun experience.

Gathering the sap

The amount of sap we gather varies from day to day and from tree to tree. Some trees are big producers; filling their buckets with startling ease. A tree that isn’t as healthy or doesn’t have as large of a spread of branches overhead will produce much less. But with 275 taps, even if every tap only produces an average of one gallon of sap in a day, that’s a lot of sap to boil!

Our sap has averaged 1.5% sugar content this year, which means it takes 58 gallons of sap to produce 1 gallon of syrup! That’s a lot of work for a small yield…which may help you understand the high price of a gallon of pure maple syrup. The entire process is incredibly labor intensive.

Sugar shack

After we gather the sap, we haul it back to the main farm to boil it down in the little “sugar shack” near my parents’ farmhouse. It takes our evaporator an hour to boil down 30 gallons of sap. So, a big day means ten hours of work in the sugar shack. My dad, my husband, and I all take shifts running the evaporator. The evaporator allows the sap to flow through a series of pans as the water boils off and the remaining liquid increases in sugar content and density. When the syrup flows into the final pan, we monitor the temperature until it reaches its finished temperature of 219 degrees.

Running the evaporator means: (1) pumping the sap into the preheat tank, (2) monitoring the fluid levels to make sure a constant flow is feeding into the evaporator, (3) feeding the roaring fire every 5-10 minutes to keep the boil going, and (4) constantly checking the temperature of the syrup. Finally, we draw off the finished syrup, opening the nozzle and trickling it through a triple-layered filter to remove any impurities before we bottle and seal it.

Sugaring safety

The sugar shack is a cozy, steamy place to be on a chilly late winter night, but it is also a frightening place to have children! The evaporator fills the space like a fiery beast, breathing out smoke and spewing maple syrup. We are ever-conscious of the dangers of having little ones around this fiercely hot boiler. The rule is that if they are in the sugar shack, they have to be sitting down in one of the seats along the wall.

Most of the daylight hours the children spend running and swinging and climbing trees outside anyway. Sometimes after dark on a chilly winter evening, after they are worn out from playing and working outside all day, we get out a tiny portable DVD player and have a family movie night while we boil. It keeps everyone still, safe, and warm together. We keep a picnic table nearby and eat our meals at the sugar shack. March picnics are a real thing during sugar season!

Dedication to the craft

This year’s maple season has been a good one, with some major runs and long boils. Usually, my husband does the majority of the boiling after his day job. He runs the evaporator till late in the night, then gets up at 4:30 a.m. to go to work again. This year, I’ve also spent a lot of hours boiling sap during the day, just to keep up with our sap flow. We’ve also been keeping our homeschooling days going on the run. Plus, I’m constantly trying to watch out for our two littlest ones! They are all independent, busy, outdoors-loving rascals who love to run around the farmyard, play on the swings near the sugar shack, and help Grandpa with his chores in the barn.

I have spent the last couple weeks a little wild-eyed and wild-haired. I’ve been shoving wood in the evaporator, checking the temperature and fluid levels, then dashing back outside to do a head count on the kids. One on the swing behind the sugar shack. One doing school on the hale bales in front of the sugar shack. One reading in the top of the juniper bush near the swings. One headed to the barn to see Grandpa. With everyone okay for the moment, I hurry back to check on the syrup. Every time I’ve been about to lose my mind, Grandma or a friend has arrived to help me out. I have been so blessed by their extra hands and eyes.

End of the season

Despite the hard work and busy days, the kids get up every morning and ask me when we are going to the farm. If our toddler even thinks she hears something about going to the farm, she’s racing for her boots and coat. But the calendar has turned to spring and the maple season is beginning to wrap up as the days warm and the trees begin to bud out. When the trees bud is determined by the number of days we’ve had over 50 degrees. We are nearing that limit for the maple trees. The sap begins to turn cloudy and sour-smelling and the flow slows down. Soon we will pull our taps, wash hundreds of buckets, and clean out the evaporator so everything will be ready for next year as the rhythm of the seasons continues.

Leslie Alvis is a wife, mom, follower of Christ, and lover of all things outdoors. She uses writing and photography as ways to keep her sanity amidst the chaos of rearing and homeschooling four children. Outdoor activities with her family are some of her favorite things. You can see more of their family’s adventures on Instagram at @c_l_allofus.

Comments

2 responses to “Tapping Trees & Making Maple Syrup with Kids”

-

[…] Have you ever considered tapping a maple tree? The whole concept of tapping maple trees, collecting sap and creating your own syrup is something that fascinates me! For hundreds of years, residents of the North American continent have tapped holes in maple trees in late winter. They’ve collected the sweet sap that flows through the trees as the days warm above freezing, and boiled it down into pure maple syrup. Last year we bought a couple of taps, hoses, and buckets to give this a try in our backyard. We didn’t collect enough to make much syrup, but the process was fascinating and definitely taught us a lot about foraging and where our food comes from. If you want to know more, we have a great post on Tapping Trees & Making Maple Syrup with Kids. […]

-

Hi, I watched your story on TV and wanted to support the kids doing the work for making the syrup. How can I make a purchase?

Leave a Reply